There are numerous hazards in commercial kitchens. When mismanaged, these dangers can lead to serious injuries or fatalities. It’s important to reduce the risk of injuries, from slips and falls to burns and chemical hazards, by practicing the following safety measures.

How do commercial kitchens reduce safety hazards?

Step 1: Avoid Overcrowding

A small commercial kitchen can become quickly and dangerously overcrowded by employees. An unnecessary number of staff in the kitchen at one time increases the risks of spills, falls, and slips. A kitchen area that flows easily, however, reduces the risk of potential hazards.

Avoid overcrowding by allowing only the necessary number of staff to work in it at any given time. Clear all entryways and exits of clutter. Remove stacks of boxes from the floors and against the walls. An unobstructed path around the commercial kitchen significantly improves safety for all employees.

Step 2: Decrease Chemical Hazards

Coming into contact with chemicals can be dangerous. Chemicals are often necessary to clean and sanitize the commercial kitchen. When used improperly, these chemicals and sanitizers can cause rashes or burns on the skin. Always follow the instructions on the bottles to ensure correct use.

Further, protective measures include storing all chemicals and cleaners in a dry and secure location. Ensure the bottles are clearly marked. Kitchen staff who clean the commercial area daily are urged to wear proper safety gear, such as eye protection and gloves.

Step 3: Prevent Equipment-Related Injuries

Working with machines, such as those that slice and cut, comes with potential risks. A number of workplace injuries result from the incorrect use of the equipment or when kitchen staff are inadequately trained. It’s important to lower the risk of injury by adhering to best safety practices.

An effective safety measure is to properly train kitchen staff on how to use the machinery. Employees who are tired, ill, or under the effects of alcohol should not operate equipment. Loose clothing and unbound hair can get tangled in the equipment, so mandate well-fitted clothing and hairnets.

Step 4: Reduce Burn Risks

Commercial kitchen staff work frequently with heated surfaces, direct flames, and hot oils. Serious injury can result from handling hot pans and pots or coming into direct contact with flames and electricity. Scalding can also occur upon contact with boiling liquids, steam, and oils.

When operating fryers or grills, employees can significantly reduce dangers by avoiding filling the baskets more than half full. Advise kitchen staff to never stand too close to the oil or lean over it. Operate equipment only at the manufacturer-recommended temperatures.

Heat-resistant clothing should be worn to minimize the risks. Burns can also be avoided by developing safe systems, like turning pot handles inward to prevent accidents, using a trolley to carry hot liquids, and cleaning up liquid spills immediately. Also regularly maintain all equipment.

Consider installing used cooking oil disposal equipment with direct connection from the fryers to the used cooking oil tank or schedule used cooking oil pickups from a reputable company. Either is safer than asking kitchen employees to haul hot oil to an outside receptacle for disposal. The oil transfer process is also simplified, eliminating the risks of burns.

Step 5: Decrease Knife Injuries

During the food preparation process, vegetables are sliced, and meat is boned. Injuries to hands and fingers are common in commercial kitchens. Most knife cuts are the result of using a dull blade or using the wrong knife to slice a food product.

Reduce the risk of knife injuries by keeping all kitchen knives sharp; dull blades are more likely to slip off the food and injure the finger. When trimming or deboning, staff should cut away from their body. Advise kitchen staff to focus while cutting rather than hold conversations.

Step 6: Avoid Fire Hazards

Commercial kitchens are stocked with fuels, flammable liquids, and gases, all of which can cause severe injury or damage. Gas ranges, ovens, deep-fat fryers, grills, and hot plates are just a handful of the many primary fire hazards in the commercial kitchen.

Prevent fire-related accidents by adequately training and supervising kitchen staff. For instance, never leave equipment on without supervision. Ensure thermostats are functional and not faulty. Schedule periodic inspections of equipment to look for signs of premature wear and tear and clean it according to the manufacturer’s recommendations.

Clogged grease traps are potential fire hazards. Methane, hydrogen sulfide, and carbon dioxide can spew out of a clogged grease trap; not only are these gases flammable, but they may be toxic. Regularly cleaning the grease trap with the help of a professional grease trap cleaning company avoids risks.

Thorough training of staff is the most effective way to reduce safety hazards in the commercial kitchen. Also important is hiring a qualified commercial kitchen service provider, like Mahoney Environmental, to regularly maintain equipment and reduce the risks of fires and other preventable perils.

We provide a wide range of essential services to help keep commercial kitchens running optimally. Our grease trap cleaning service is necessary to prevent clogs, messy backups, and breakdowns. Skilled technicians utilize proper tools and possess the expertise to thoroughly clean the grease traps.

Restaurant owners can conveniently schedule our service, and we’ll arrive on time to clean the interior and exterior of the grease traps; if necessary, we provide repairs. Once all build-up is removed, our techs provide an inspection report. Our 24/7 emergency cleanup is also available.

A well-run commercial kitchen relies on a cooking oil disposal system. Mahoney Environmental’s used cooking oil recycling program is the solution for restaurants that want their used oil picked up on a regular schedule. In select markets, we deliver fresh cooking oil to ensure you have a regular supply too.

Mahoney Environmental is a valuable partner for restaurants that aim to reduce safety hazards in their kitchen. With our cooking oil recycling program and grease trap cleaning services, your kitchen will run smoothly. Contact us to schedule any of our services and significantly improve your kitchen safety.

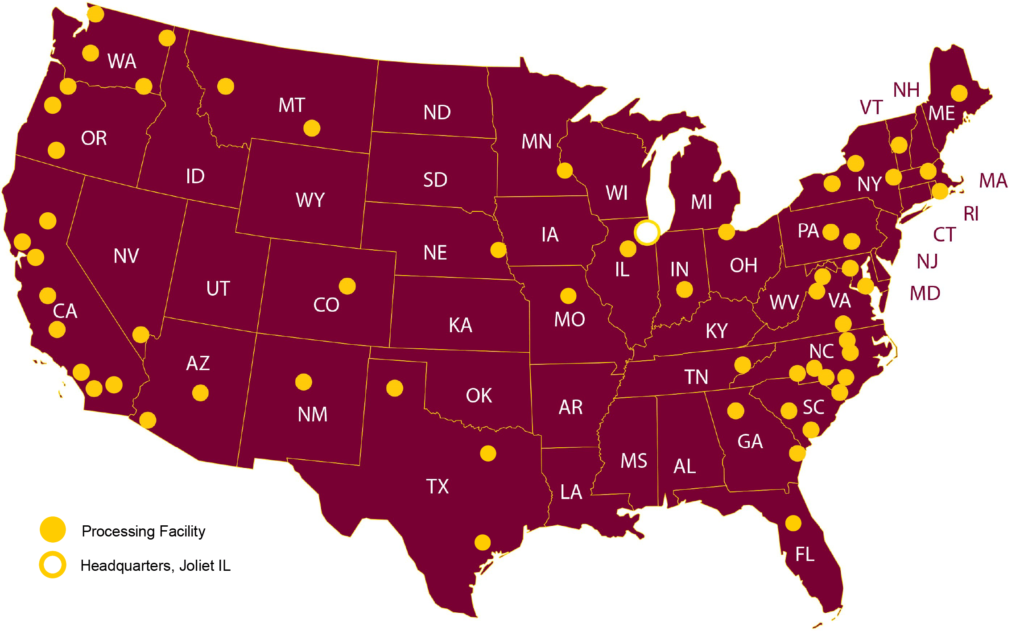

You can call Mahoney at (800) 892-9392 for more about our used cooking oil pickup and recycling services. We are proud to serve food establishments across the country including Atlanta, Austin, Baltimore, Baltimore, Boston, Chicago, Cleveland, Columbus, Dallas, Denver, Houston, Indianapolis, Kansas City, Los Angeles, Louisville, Miami, Nashville, New York, Oklahoma City, Orlando, Philadelphia, Phoenix, Raleigh, San Diego, San Antonio, Seattle, Tampa, Tucson, Washington DC and the surrounding areas.

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392