When running a restaurant, there are many things that you have to worry about to keep your business running smoothly, including the collection and disposal of the used cooking oil.

Mahoney Environmental helps give restaurant owners one less thing to worry about by handling the pickup and removal of used cooking oil.

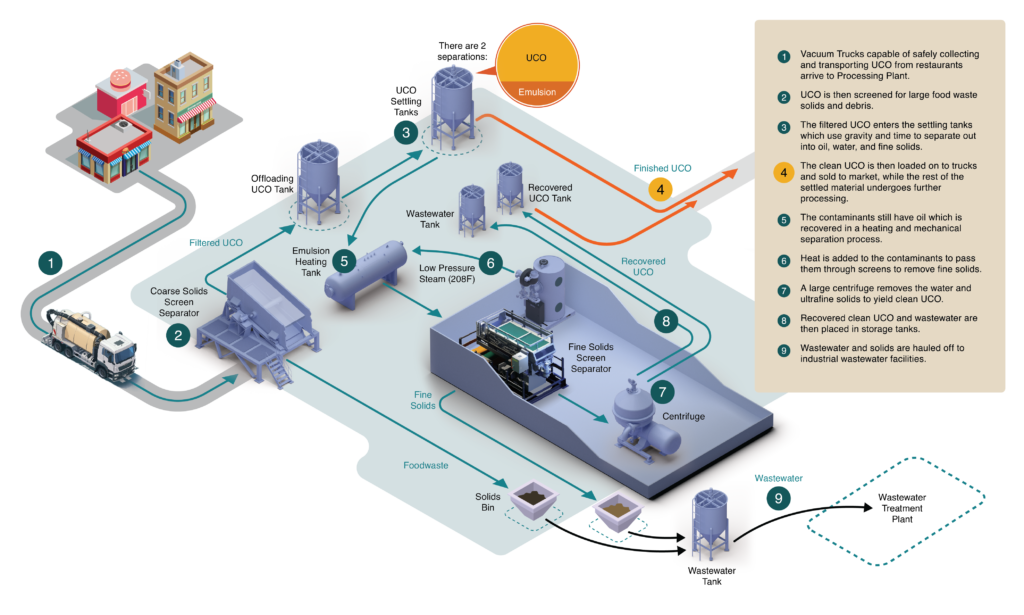

All of the cooking oil that we collect is treated and reused in the production of renewable diesel. If you would like to learn more about what happens to the used cooking oil we collect, you can read about the different steps below.

Used Cooking Oil (UCO) is transported to Mendota Agri-Products for processing by Mahoney Environmental. Raw UCO is emptied out of the trucks and in to the receiving pit.

In the receiving pit, the UCO is heated up to a temperature that allows the liquid to drain through a screen at the bottom of the pit. This temperature will not exceed 190 degrees and is monitored by a probe connected to a chart recorder.

While the grease is heating, an auger carries excess solid material out. The solid material is then separated from other debris and is dumped into the trash.

The liquid is then pumped to a roto-strainer, where solids smaller than 3/8″ are separated. Here, glass and gravel are taken out and sent to the trash. The liquid is moved to a settling tank.

Once the UCO is in the settling tank, it is heated up to 212 degrees and sits for 24 hours. This process allows the material to separate into three layers: water, emulsion, and oil.

The water is drained off from the bottom and sent to the waste-water operation to be processed in an Anaerobic digester. The emulsion (water, oil, and solids that will not separate through gravity), is sent to the evaporator for processing.

The finished UCO is checked for free fatty acid levels and solids percentage and is then sent to storage for shipment. The emulsions are blended into batches that are run through the evaporator. In the evaporator, the emulsion is re-circulated and heated under vacuum. This results in the water evaporating and releasing the solids from the oil.

Once the discharge temperature reaches 190 degrees, the water is flashed off in vapor form. The vapors are sent to an air condenser where fans are used to cool the vapors, changing them back into water, which is then sent to waste water for processing. Non-condensables are sent to the boilers to be incinerated.

The oil and solids are then sent to the centrifuge where they are separated. The solids, which are primarily flour and starches from the frying process, are sold as a low protein animal feed, while the oil is sent to storage. The oil being discharged from the centrifuge is periodically checked for solids.

Finished UCO is also brought in from outside of the plant. This oil is sent straight to storage. When the oil is in storage, free fatty acids are measured, and oil is blended together per customer specifications. A sample of the batch is taken and sent to a lab where it is tested for pesticides, insecticides, and PCB.

Nearly 100% of the Used Cooking Oil collected by Mahoney Environmental is sold as a feedstock for renewable diesel and sustainable aviation fuel. Mahoney is proud to be part of the solution.

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392