Grease and water don’t mix, especially when they travel through the sewer lines. Due to this concern, grease traps are essential for operating commercial kitchens.

Wastewater from foodservice businesses, laden with fats, oils, and grease (FOG), originates from kitchen sinks and navigates through pipes to reach treatment facilities. This FOG buildup underscores the necessity for routine restaurant grease trap cleaning.

Treatment plants are ill-equipped to process grease. Additionally, when grease coagulates, it clogs pipes, leading to sewer backups or sanitary sewer overflows. To mitigate these issues, local and state regulations mandate the installation of grease traps and interceptors in commercial kitchens, safeguarding against sewage blockages.

Grease traps and interceptors are essential not only for restaurants but also for a variety of establishments with commercial kitchens including hospitals, malls, schools, and more. These facilities must install grease traps to prevent blockage in the sewage line from grease and avoid fines resulting from such blockages. When a sewage blockage occurs, it requires repairs to the internal plumbing system, causing downtime and losses for the affected business.

The installation of grease traps or interceptors is not the only requirement; regular maintenance is crucial. Traditional grease traps need to be cleaned once they are filled to 25 percent of their capacity with grease, but it is important to work with your grease management company to determine the correct cleaning schedule. Neglecting regular cleanings prevents the grease traps from effectively filtering the wastewater, leading to the accumulation of grease and oils in the sewage system which results in messy sewage backups.

Whether an establishment has a large-scale kitchen or a smaller one, a grease trap or grease interceptor is required. While both a grease trap and interceptors help prevent sewer line clogs, there are distinct differences between the two. It is important to understand how these options differ and how they help filter FOG from your wastewater to protect the sewer system and keep your business in compliance with local ordinances.

The following are the key differences between grease traps and grease interceptors.

1. Regularity of Cleanings

Due to the small size of grease traps, these mini traps require cleaning more often. Since grease traps are generally small, the grease builds up faster inside them. Ideally, grease traps should be cleaned monthly by specialists or daily by employees.

Grease interceptors are larger. As a result, grease interceptors can hold more grease and require cleaning less often. Typically, grease interceptors should be cleaned once every three months.

Businesses that have a grease trap or grease interceptor on the premises should be aware of the ¼ rule. The ¼ rule provides a good estimate on when to clean on out the grease trap or grease interceptor. When the trap has filled to ¼ of its size, the grease should be pumped out according to the maintenance schedule created by your grease management company

2. Flow Rate

Low volume flows require a grease trap. The grease traps work well with low water pressure (less than 50 gallons per minute).

Kitchens with a high volume of flow, such as more than 50 gallons per minute, will have a grease interceptor. Large-scale establishments install grease interceptors, as they are fully equipped to handle the extensive grease flows through the drains.

3. Location

Grease traps, being relatively smaller than grease interceptors, are installed beneath the kitchen sink.

Grease interceptors, however, with their large size, are installed outside of the building or underground manholes. Local ordinances may dictate where a grease interceptor should be located. Grease interceptors work well if the devices are located close to the fixture they serve. Ideal locations include an adjacent room or under the fixture served.

Foul odors emanate from grease interceptors so they should be placed away from the areas where restaurant customers frequent.

4. Size

Grease traps are usually the size of a bread box. Sizing can vary, usually between 10 gallons and 500 gallons.

Grease interceptors, with their larger holding capacity, are typically the size of a mini fridge. Grease interceptors feature a holding capacity of 500 gallons on up.

An establishment can figure out the ideal size for a grease trap or grease interceptor by considering whether it is a facility with low, medium, or high grease production. For instance, a convenience store, delicatessen, snack bar, or sandwich shop will produce low grease flows. A coffee house, pizzeria, and ice cream parlor typically produce medium grease flows. High grease flows are produced by cafeterias, diners, and family restaurants.

5. Grease Pumping

While grease traps may be cleaned by hand, grease interceptors require the service of specialists. Technicians operate a large hose that pumps the grease from the interceptor to a truck equipped with a tank that holds fluids.

6. Material

Grease traps are made from materials such as steel, plastic, fiberglass, and PVC. Rusted grease traps cannot be repaired and must be replaced. Cracked grease traps, too, cannot be repaired and should be replaced.

Grease interceptors are made from cement, PVC, or fiberglass materials that can withstand the elements while being situated outside.

7. Local Mandates

As mentioned above, there are local ordinances regarding the use of grease traps and grease interceptors that all foodservice establishments must follow to avoid violations that can result in fines or even business closure.

However, the mandates are usually different for grease traps and grease interceptors. It is important to understand the specific mandates within your local municipality to ensure that you comply with these ordinances.

Benefits of Using Grease Traps and Grease Interceptors

While there are key differences, grease traps and grease interceptors both accomplish the same thing, they filter FOG from the wastewater which protects the sewer system and the natural environment. The following are the benefits of having well maintained grease traps and grease interceptors in your commercial kitchen:

- Grease traps and grease interceptors are durable and can last for many years with proper maintenance. Grease traps are made from stainless steel and grease interceptors are made from cement, PVC, or fiberglass materials for excellent durability in outdoor conditions.

- Grease traps and grease interceptors help extend the life of septic tanks by filtering the FOG.

- Keeping grease traps and grease interceptors clean and maintained allows them to efficiently filter FOG which protects the natural environment. Taking steps to protect the environment can improve the public image of your business.

- Grease traps and grease interceptors reduce the risk of backflows that can flood your kitchen and cost your business time and money.

- Your business can help protect your local environment, including rivers and streams, by effectively filtering FOG from your wastewater with functional grease traps and grease interceptors.

Grease Trap Cleaning and Maintenance from Mahoney

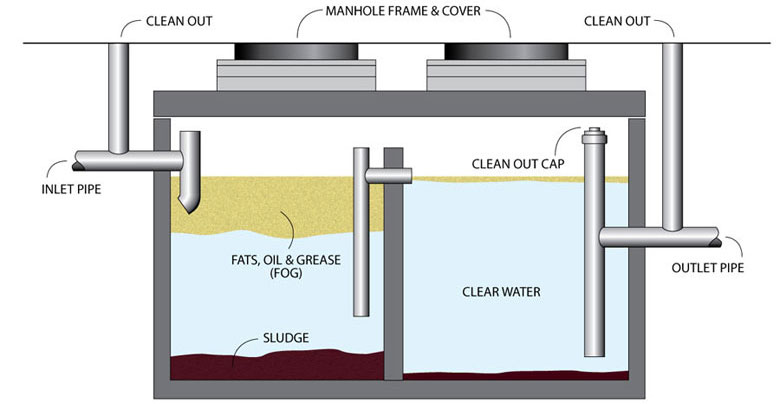

The accumulation of fats, oils, and grease (FOG) in food wastewater poses a significant threat to sewer lines. The use of grease traps to prevent FOG from getting into the sewer system dates as far back as the Roman Empire. The modern grease trap design was invented in 1884 and its technology has remained nearly unchanged ever since. Whether the unit is a grease trap or grease interceptor, the technology works the same. FOG floats to the surface, leaving the wastewater to flow into the sewage system.

When your food establishment requires the services of the country’s most reputable used cooking oil recycling experts, turn to Mahoney Environmental. With over 70 years of dedicated service to the nation, Mahoney Environmental offers an extensive list of services that are advantageous to the foodservice industry.

Satisfied customers have benefitted from Mahoney Environmental’s cooking oil equipment installation services, fresh oil delivery, and waste cooking oil collection and recycling. Focused on sustaining a clean and responsible cooking environment, our team at Mahoney Environmental provides exceptional service and industry standard automated equipment.

Related Articles:

Complete Guide for Cleaning Grease Traps in Commercial Kitchens

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392